11 Critical Questions for Sweets & Snack Food Manufacturers:

Unlocking Success in Snacks, Candy, Chips, and Beef Jerky

When starting out in the production and packaging of snacks, candy, chips, and beef jerky,

many teams often overlook crucial questions that can significantly impact their success.

Here are the essential considerations for a successful venture.

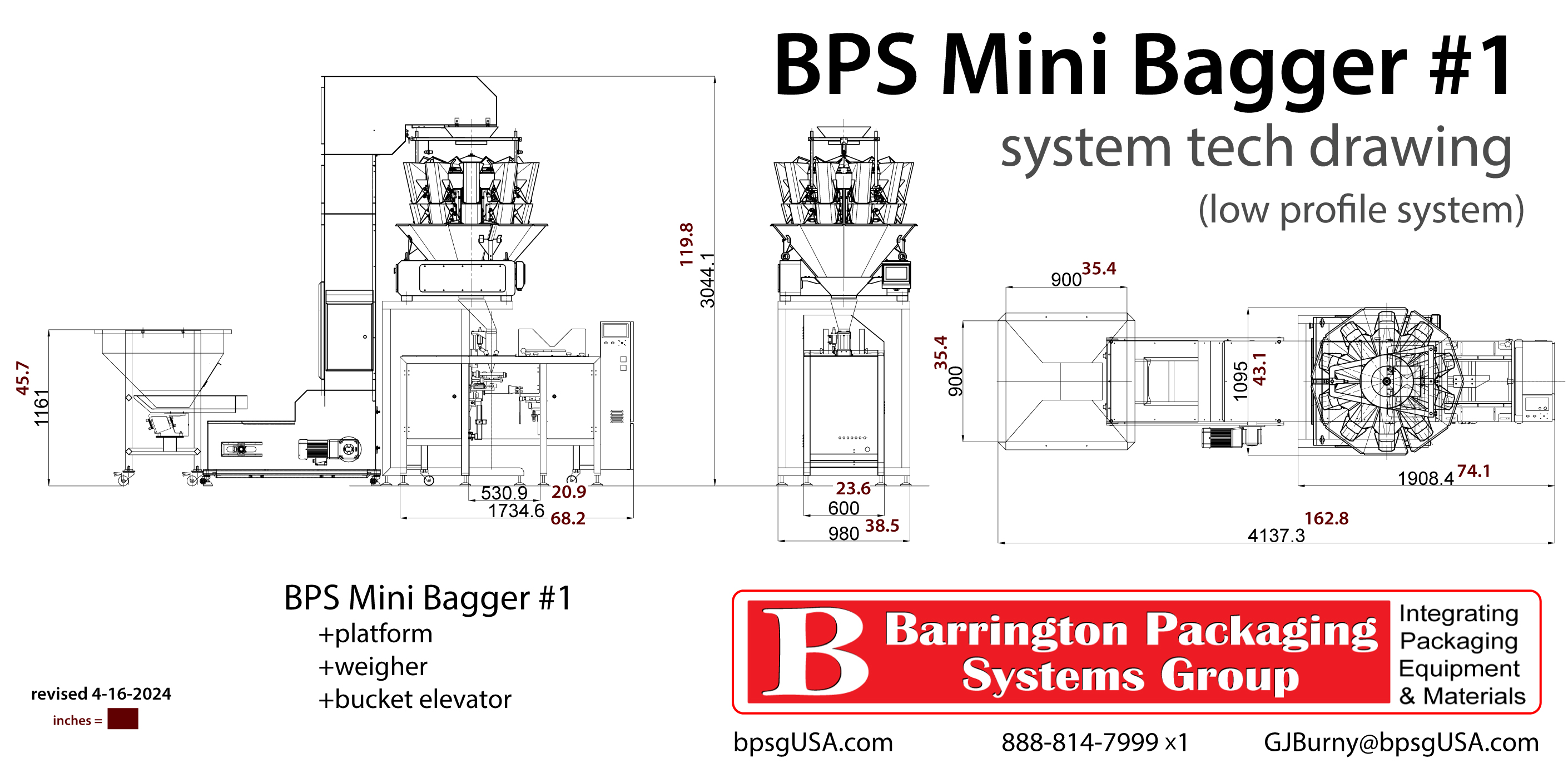

BPS Mini Bagger #1 technical line drawing showing the low profile system, including the stainless steel platform, combination scale, and Z bucket conveyor/elevator. The system is designed for low cost, efficient and precise product packaging.

BPS Mini Bagger #1 technical line drawing showing the low profile system, including the stainless steel platform, combination scale, and Z bucket conveyor/elevator. The system is designed for low cost, efficient and precise product packaging.

11 Questions from Snack Food Manufacturers:

- ✦ What ingredients should I use for optimal flavor and texture?

- ✦ How do I ensure consistent sizing and shapes?

- ✦ What packaging materials are best for preserving freshness?

- ✦ How do I achieve efficient and hygienic packaging processes?

- ✦ What labeling and branding strategies should I use?

- ✦ How do I manage production scale-up as demand grows?

- ✦ What are the regulatory requirements for food packaging?

- ✦ How can I reduce packaging waste and improve sustainability?

- ✦ What is the cost of packaging equipment and how can I finance it?

- ✦ How do I ensure customer satisfaction and build brand loyalty?

- ✦ How Barrington Packaging Can Help?

Snack Food Manufacturers Packing Sweets & Snacks. Candy, Chips & Beef Jerky

What ingredients should I use for optimal flavor and texture?

Choosing the right ingredients is crucial for creating high-quality pita chips. Experimenting with different types of flour, oils, and seasonings can help you find the perfect combination. Barrington Packaging can assist with equipment that maintains the integrity and freshness of your ingredients during the packaging process.

How do I ensure consistent sizing and shapes?

Consistency is key to product quality and customer satisfaction. Using automated cutting and shaping equipment can ensure uniformity. Barrington Packaging offers state-of-the-art machinery that can be customized to produce consistent chip sizes and shapes, enhancing product appeal.

What packaging materials are best for preserving freshness?

Selecting the right packaging materials is vital to keeping your pita chips fresh and crunchy. Consider materials that offer good barrier properties against moisture and oxygen. Barrington Packaging provides a range of packaging films and preformed bags preprinted designed to extend shelf life and maintain product quality.

How do I achieve efficient and hygienic packaging processes?

Efficiency and hygiene are critical in food packaging. Implementing automated systems can streamline your packaging process and minimize contamination risks. Barrington Packaging offers fully automated equipment systems that ensure hygienic and efficient packaging, reducing labor costs and increasing productivity.

What labeling and branding strategies should I use?

Effective labeling and branding can differentiate your product in the market. It’s essential to use clear, attractive labels that comply with regulatory requirements. Barrington Packaging can provide labeling machines and design assistance to help you create impactful branding.

How do I manage production scale-up as demand grows?

Planning for scalability is essential for long-term success. Choose equipment that can be easily scaled up to meet increasing demand. Barrington Packaging offers scalable solutions that grow with your business, ensuring you can meet market demands without compromising on quality.

What are the regulatory requirements for food packaging?

Understanding and complying with food safety regulations is crucial. Stay informed about local and international packaging standards. Barrington Packaging’s team of experts can guide you through the regulatory landscape and help you implement compliant packaging solutions.

\

How can I reduce packaging waste and improve sustainability?

Sustainable packaging is increasingly important to consumers. Consider eco-friendly materials and processes that minimize waste. Barrington Packaging offers sustainable packaging options, including biodegradable and recyclable materials, to help you reduce your environmental footprint.

What is the cost of packaging equipment and how can I finance it?

Budgeting for packaging equipment is a critical step. Explore financing options that fit your budget. Barrington Packaging has partnered with Ascentium Capital to offer flexible financing solutions, you can reach out to Trace LaBarr, CLFP making it easier to acquire the necessary equipment without straining your finances. For more click here.

How do I ensure customer satisfaction and build brand loyalty?

High-quality packaging that maintains product freshness and showcases your brand can boost customer satisfaction and loyalty. Barrington Packaging provides comprehensive solutions, from packaging design to automated equipment, ensuring your pita chips reach customers in perfect condition.

How Barrington Packaging Can Help?

At Barrington Packaging Systems Group Inc., we offer a complete range of packaging solutions tailored to meet the unique needs for your pita chips or your beef jerky you are manufacturing. Our advanced packaging equipment, including horizontal flow wrappers, small footprint high output low profile vertical form-fill-seal machines, and labeling systems, ensures efficient, hygienic, and scalable packaging processes. We also provide expert guidance on selecting the right packaging materials and complying with regulatory standards, helping you create a high-quality product that stands out in the market.

For more information on how Barrington Packaging can support your pita chip or beef Jerky manufacturing and packaging needs, contact us today at 888-814-7999 X1.