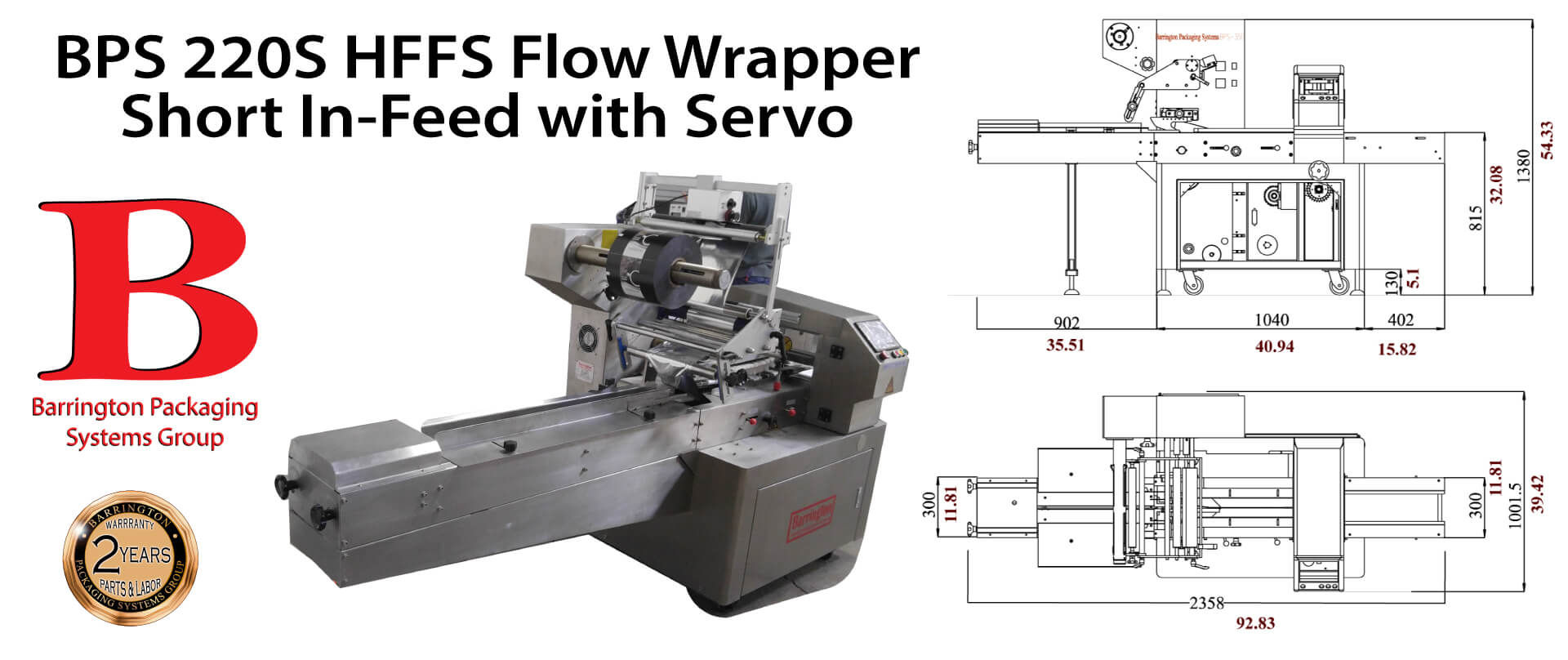

The Revolutionary BPS 220S with Short In-Feed by Barrington Packaging Systems Group Fully featured machine fully featured system with many additional options included printable .pdf

The BPS 220S is more than just a name; it's a revolution in packaging. Dive deep into what the "S" stands for – Three Servo's.

With superiority that outmatches standard analog systems, the Three Servo technology is the very pulse of digital precision in packaging.

This integration of Three Servo's brings forth a plethora of benefits for manufacturers, emphasizing both efficiency and cost-effectiveness.

How the BPS 220S Three Servo System Changes the Game:

- Digital Precision: Experience packaging like never before, with each granola bar, chocolate-covered wafer, or bagel wrapped to perfection.

- Enhanced Speed: Multiple Servo Technology amplifies speed, enabling you to accomplish more in less time.

- Reduction in Fillm and Product wastage: Featuring NO-product NO-film, and NO-GAP NO-Seal, reduced wastage with pinpoint accuracy. Every inch is optimized with Servo.

- Reliability and Consistency: Precision is nothing without consistency. Multiple Servo's assures consistent results, every time.

- Space Efficiency: This compact design of the BPS 220S is ideal for space-constrained environments, without compromising on performance.

The Automation You Need at a Price You Can Afford

Understanding the BPS 220S HFFS Flow Wrapping Process

Horizontal Form-Fill-Seal, or HFFS flow wrapping, is a trusted packaging method chosen by manufacturers globally. Ever wondered how a granola bar, a chocolate wafer, or a bagel transitions from its raw form to being securely wrapped in a clear or printed film? Here's a sneak peek:

- Infeed Conveyor: Products are systematically placed and transported to the wrapping section.

- Film Feeding: A protective film unravels, forming a protective barrier around each product, ensuring freshness and protection.

- Sealing and Cutting: Precise seals ensures each product is individually packaged, maximizing security and presentation.

- Outfeed: Hermetically sealed packages transition to further processes.

- Finished Product: The end result? A perfectly packaged product, ready for the shelf, reflecting quality and brand aesthetics.

The brilliance of the HFFS flow wrapper, particularly the BPS 220S, lies in its fusion of technology, precision, and speed. With the power of Three Servo's, precision and efficiency become the norms, not the exceptions.