888-814-7999

About Us

In the world of the manufacturing business, packaging is more than just a way to contain and

transport your products.

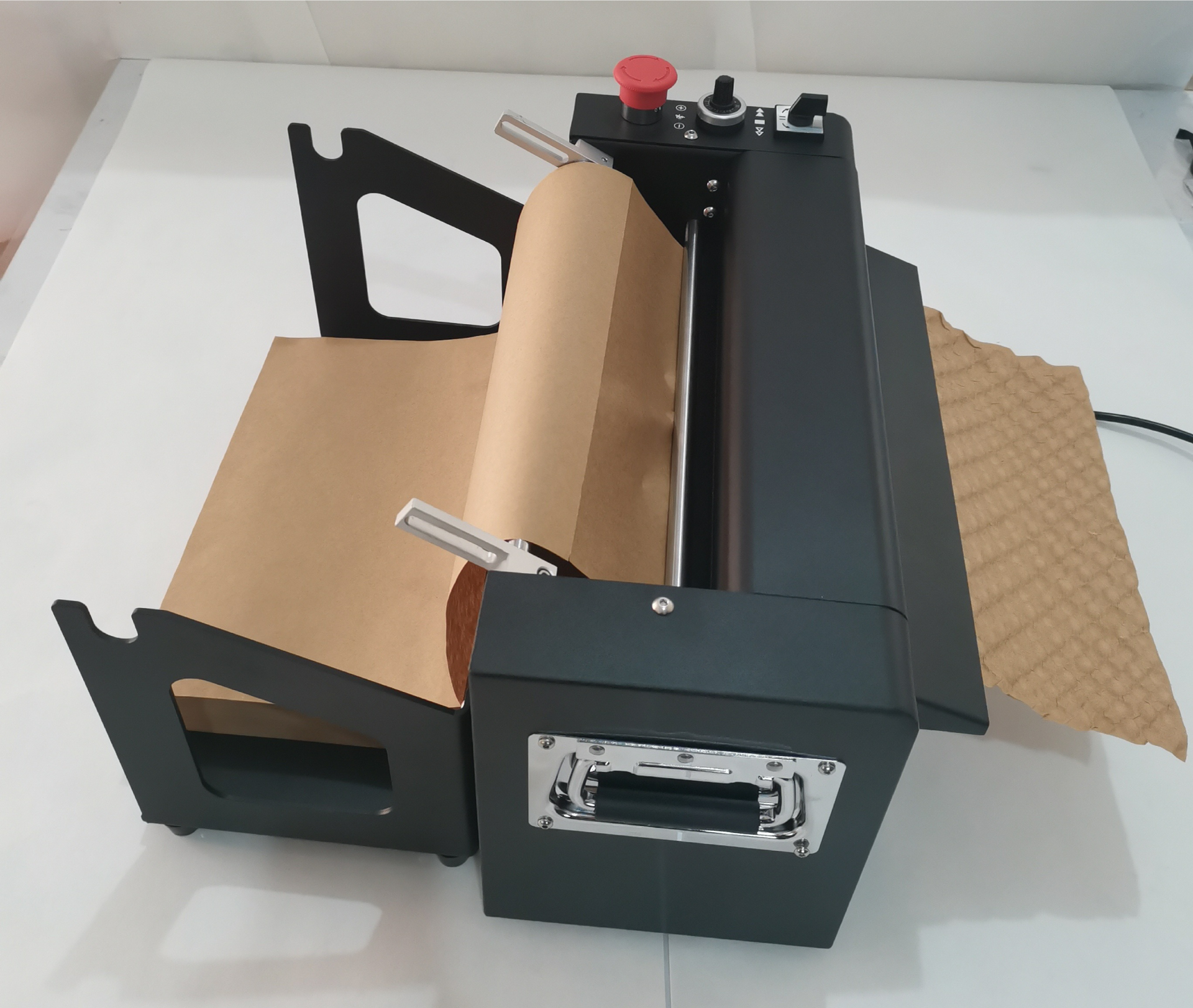

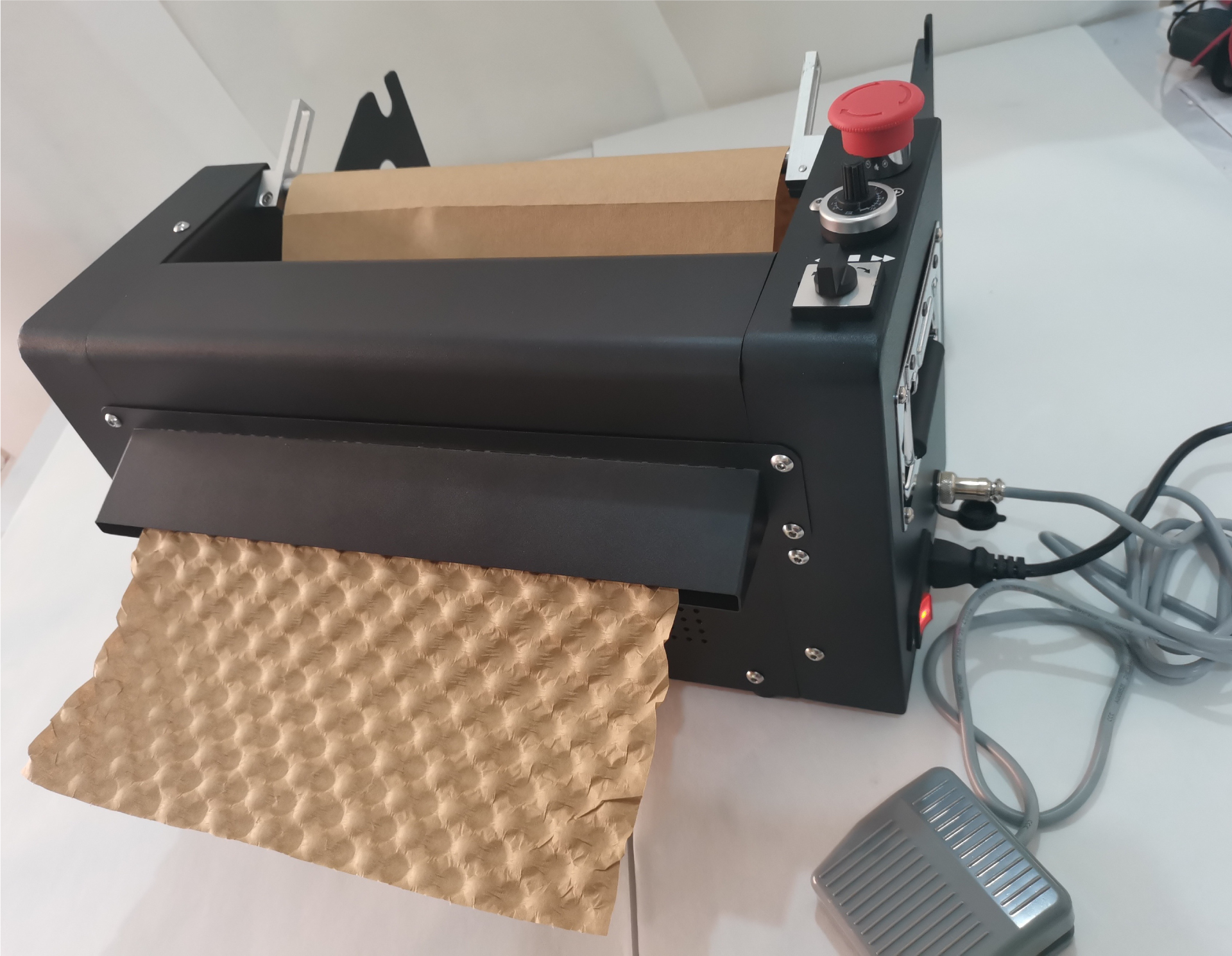

Barrington offers a comprehensive product line that includes mini baggers, stick bagers, metal detectors and check weighers, horizontal flow wrappers, vacuum tray sealers, clamshell cup filling and sealers, label applicators, and more. Experience the advantage of our Profit-Focused Manufacturing approach and realize greater profits with our state-of-the-art packaging machines.